How a Pellet Press Works

If you own a machine, it is wise to know its operation to enable you make a quick repair incase of any wear and tear. Machines are man made equipments and they are prom to destruction or faults. The pellet press is one of the machines that have grown in popularity in most economies in the world. This article will go a long way to educate people on the functions and operations of this machine that is used to make pellets. The pellets are sources of energy that are used in a pellet stove and could be used to replace oil or firewood.

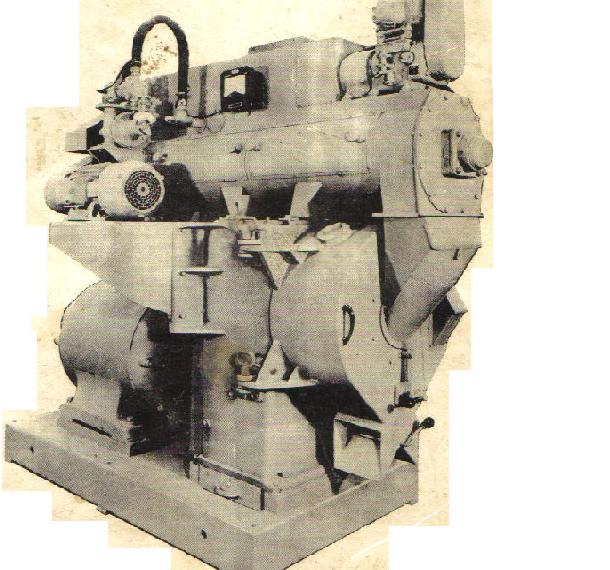

The machine is used to compress the pellets so that to make them firm and strong. The pellets are made from organic waste products like wheat bran, wood shavings or saw dust. The raw materials are placed on the funnel-like opening which is situated on top of the pellet mill. This part is called the feeder and from this entrance the organic waste is able to be digested into the machine. However; the flow of the materials should be controlled to prevent blockage in the machine. The waste is then pulled into the machine by rollers which pass them though tiny holes and due to pressure, the pellets are compressed and a compact molded stock is pushed though the rollers and dies.

The molded pellets then moves to a section that contains blades that are responsible for shaving the pellets to their original or intended sizes. These pellets are applied a die and the pellets press makes sure that the resultant results are dried and contain very little water if they have. The drying of these pellets is very important since this is the concept used to reduce the consumption of the pellets by fire. The pellets are so compact that it shall take more time for fire to destroy them. This is why this source of energy can burn for long hours without getting exhausted. After removing the pellets from the machine, they are placed in a dry area to make sure they are completely dried.